Products

Whether you’re building, remodeling, buying, or selling, we bring

seamless project execution under one roof.

Products

You Meet Expert Our

Leadership

Standard

Made from nominal scaffold tube, the standards lock vertically, (Kwikstage) with a captive expanding joint pin, which is tightened by hammering down the captive box wedge.

Open End Standard

By using open end standard, U-head jacks can be placed on top of the scaffold system, kwikstage shoring system is a smart choice when you both need scaffolding and formwork system on the construction site.

Access Standard

Access standard is used for stair or access tower.

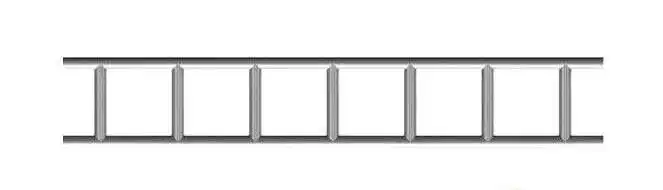

Transoms

Transoms fit into the lower 'V' pressings on the standards to carry steel boards and secure the standards together. The transoms are installed horizontally and at 90 degrees to the ledger.

Ladder Transom

Clamps on to ledgers to allow steel boards to seat in. Allowing sufficient room for ladder access.

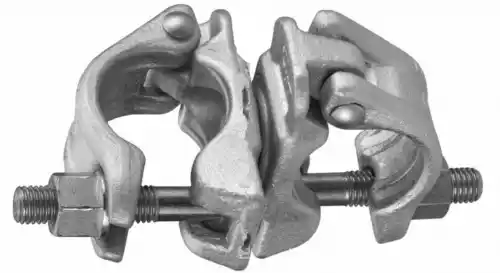

Braces

The brace provides an additional stabilizing influence on the scaffold. Made from nominal scaffold tube, the braces are flattened at each end, to accept a swivel 'c' coupler with a captive wedge. Braces come in various lengths.

Steel Planks

Steel Planks combine light weight with strength to fit neatly into the inverted 'T' seat of transom providing a completely flush working deck with capacity well in excess of the greatest allowable bay loading in 675 kgs.

Infill Plank

Infill plank is designed to fill up the gaps between transom and plank, to make a complete surface.

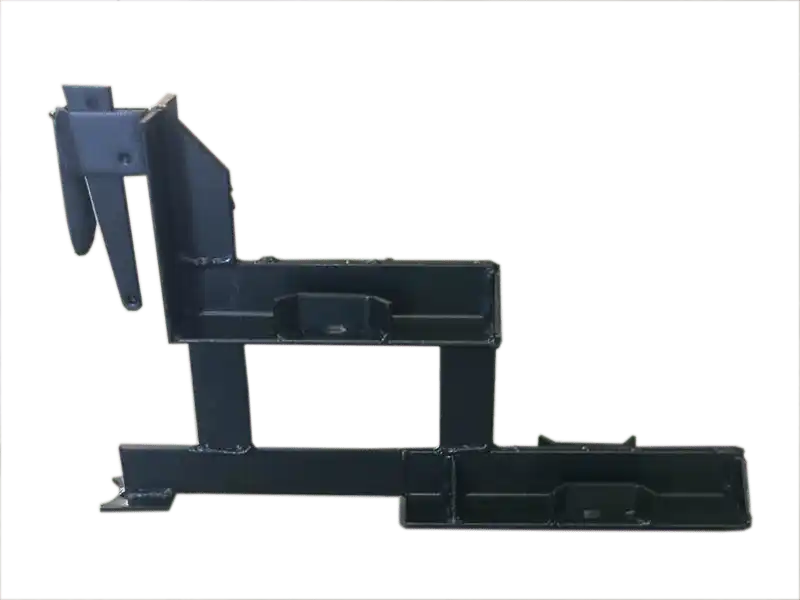

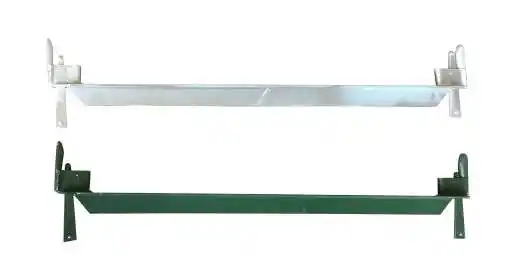

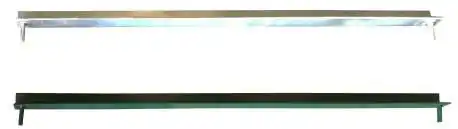

Tie Bars

Tie bars are manufactured from 4mm X 40mm steel angle in three basic lengths to suit the individual bay sizes. Tie bars are used whenever 2 or 3 board stage brackets are fitted, to eliminate lateral movement and ensure positive location of the boards.

Corner Brackets

Corner Brackets are used in tandem with Hop Up Brackets to fill any corner gaps that may occur in the scaffold's design.

Kickboards

Kick Boards are usually used for safety purposes, preventing the materials & heavy stuff from falling down from the platforms.

8488

Safety

Incidents

Incidents

8582

+

Happy

customers

customers

82.83

+

Upcoming

Projects

Projects

8188

+

years of

experience

experience

.webp)